Introduction: Beyond Surface-Level Price Comparisons

In the sophisticated world of modern construction materials, the decision between traditional metal roofing systems and advanced metal shingle roofing represents more than a simple cost comparison—it embodies a strategic choice about project positioning, long-term value, and market differentiation. For building professionals, importers, and contractors who understand that true cost extends far beyond initial material expenses, this analysis delves into the nuanced value propositions of both roofing approaches.

At ROOFGLORY, with our advanced manufacturing capabilities in Linyi, Shandong, China, we’ve developed both standing seam metal roofing and architectural metal shingle systems that cater to distinct market segments and project requirements. Our perspective extends beyond manufacturing to encompass the practical realities of installation, maintenance, and long-term performance that ultimately determine the true cost of ownership for building professionals and their clients.

Understanding the Fundamental Differences: System Architecture and Installation Methodology

Traditional Metal Roofing Systems

Often referred to colloquially as “tin roofs” despite their evolution into sophisticated engineered systems, traditional metal roofing typically involves large-format panels installed in continuous lengths across the roof structure. These systems, particularly standing seam configurations, represent a mature technology with proven performance characteristics spanning decades of application across commercial, agricultural, and residential projects.

The installation methodology for traditional metal roofing requires specialized knowledge of panel engagement systems, clip attachments, and expansion accommodation details. While the learning curve for proper installation can be steep for crews unfamiliar with metal roofing principles, the system efficiency achieved through large-format panels often translates to rapid coverage of expansive roof areas. This efficiency becomes particularly valuable on commercial projects with large, uninterrupted roof planes where the economies of scale significantly favor panel systems over individual shingle installation.

Metal Shingle Roofing Systems

Metal shingle roofing represents an evolution in metal roofing technology that combines the performance advantages of metal with the architectural familiarity of traditional shingle aesthetics. These systems typically consist of individual shingle units manufactured from steel or aluminum with protective coatings and embossed patterns that replicate the appearance of wood shake, slate, or traditional asphalt shingles while providing substantially enhanced durability and weather resistance.

The installation process for metal shingles bridges the gap between conventional shingle application and metal roofing techniques. While requiring understanding of metal roofing principles regarding ventilation and expansion, the installation methodology often feels familiar to roofing crews experienced with traditional shingle systems. This hybrid approach can reduce training requirements while still delivering the performance advantages associated with metal roofing, making metal shingles an attractive option for contractors expanding their service offerings into premium roofing solutions.

Material and Manufacturing Considerations: The Foundation of Long-Term Value

Substrate Selection and Protective Coatings

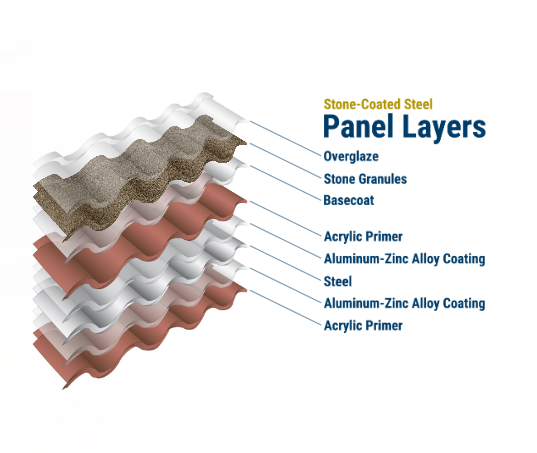

Both traditional metal roofing and metal shingle systems begin with high-quality steel substrates, though the specific alloy compositions and gauges may vary based on performance requirements and forming characteristics. At ROOFGLORY, our manufacturing process starts with galvanized steel treated with aluminum-zinc alloy coatings that provide exceptional corrosion resistance, forming the foundation for long-term performance in diverse environmental conditions.

The protective coating systems applied to these substrates represent another critical differentiator in long-term performance and aesthetic retention. Our advanced paint systems incorporate multiple layers including primer, color coat, and protective clear coat formulated with UV-resistant polymers and flexible resins that maintain their integrity through decades of thermal cycling and weather exposure. These coating technologies ensure that both our panel and shingle products maintain their aesthetic appeal while providing maximum protection against environmental challenges.

Manufacturing Precision and Quality Control

Manufacturing Precision and Quality Control

The manufacturing approach for metal shingles involves additional forming operations compared to traditional metal panels, with precise embossing and profiling that creates the dimensional appearance of traditional roofing materials. This additional manufacturing complexity requires sophisticated tooling and precision controls to ensure consistent appearance and performance across production runs. At our Linyi facility, we’ve invested in advanced forming technology that maintains exacting tolerances while accommodating the complex geometries of architectural shingle designs.

The quality control processes for metal shingles extend beyond dimensional verification to include comprehensive testing of coating adhesion, color consistency, and interlocking performance. Each production batch undergoes rigorous evaluation to ensure that every shingle meets our performance standards, providing building professionals with the consistency required for successful project execution and long-term client satisfaction.

Installation Economics: Labor Efficiency and Project Management Implications

Labor Requirements and Crew Specialization

The labor profile for traditional metal roofing installation typically involves smaller, specialized crews with specific training in metal panel systems. While these crews may command higher hourly rates due to their specialized skills, their efficiency on appropriate projects often results in lower total labor costs per square foot of roof area. This efficiency advantage becomes increasingly pronounced on large, simple roof structures where long panel runs minimize seams and connections.

Metal shingle installation generally requires larger crews working in production-line fashion, similar to traditional shingle application but with attention to metal-specific details regarding fastening and expansion. The learning curve for crews transitioning from asphalt shingles to metal shingles is typically less steep than for traditional metal panels, potentially reducing training investments and broadening the pool of qualified installers. This accessibility can be particularly valuable for contractors operating in regions where specialized metal roofing labor is scarce or prohibitively expensive.

Project Scheduling and Weather Considerations

The installation timeline for traditional metal roofing often benefits from the rapid coverage achievable with large-format panels, particularly on commercial projects with extensive roof areas. This scheduling advantage can be crucial in regions with limited weather windows for roofing work or on projects with aggressive completion timelines. The ability to quickly weather-in a structure provides downstream trade partners with earlier access, potentially compressing the overall project schedule.

Metal shingle installation typically proceeds at a pace more comparable to traditional shingling operations, though still generally faster than premium asphalt shingle products due to the larger unit size of metal shingles. The installation process is generally less weather-sensitive than asphalt shingles, which require specific temperature ranges for proper sealing. This expanded weather window can extend the viable roofing season in temperate climates, providing contractors with greater scheduling flexibility throughout the year.

Performance Characteristics: Beyond Basic Weather Protection

Durability and Weather Resistance

Both traditional metal roofing and metal shingle systems offer exceptional durability compared to organic roofing materials, with service lives typically extending 40 to 70 years depending on environmental conditions and maintenance practices. The non-porous nature of metal provides inherent resistance to moisture absorption, preventing the rot, mold, and degradation that can affect organic materials over time.

The impact resistance of metal roofing systems significantly exceeds that of asphalt shingles, reducing vulnerability to hail damage and falling debris. This durability advantage translates to reduced insurance premiums in many regions and minimized maintenance requirements throughout the product’s service life. For building professionals managing multiple properties or offering warranty coverage on their work, this reduced liability exposure represents substantial financial value beyond simple material cost comparisons.

Thermal Performance and Energy Efficiency

The thermal performance characteristics of metal roofing have evolved significantly from the simplistic perception of metal as a conductor of heat and cold. Modern metal roofing systems, including both panels and shingles, can be integrated with advanced ventilation approaches and reflective pigment technologies that significantly reduce heat transfer and improve overall building energy performance.

The reflective properties of metal roofing surfaces, particularly those utilizing light-colored or specialized cool-roof coatings, can reduce cooling costs by 10% to 25% in warm climates by minimizing solar heat gain. This energy efficiency advantage has become increasingly valuable as building codes evolve to address sustainability concerns and building owners seek to reduce operational expenses. The potential contribution to green building certification under programs such as LEED further enhances the value proposition for environmentally conscious projects.

Aesthetic Considerations and Market Positioning

Architectural Integration and Design Flexibility

Traditional metal roofing panels, particularly standing seam systems, offer a clean, contemporary aesthetic that complements modern architectural styles. The continuous lines and minimal visual segmentation create a unified appearance that many architects and designers prefer for commercial structures and contemporary residential designs. The wide color selection available in modern paint systems provides additional design flexibility while maintaining the distinctive character of metal panel roofing.

Metal shingle systems provide a different aesthetic approach that preserves traditional architectural character while delivering modern performance. The ability to replicate the appearance of wood shake, slate, or traditional tile makes metal shingles particularly valuable for renovation projects where maintaining historical accuracy is important, or for new construction in communities with architectural guidelines. This design versatility allows builders to meet aesthetic expectations without compromising on performance or longevity.

Market Perception and Client Education

The market perception of traditional metal roofing varies significantly by region and application. In commercial construction, metal roofing is widely recognized as a premium, high-performance option, while in residential markets, perceptions may be influenced by historical associations with agricultural or industrial applications. Educating clients about the evolution of metal roofing technology and its application in premium residential projects represents both a challenge and opportunity for building professionals.

Metal shingles often face fewer perceptual hurdles in residential markets due to their familiar appearance, though the value proposition regarding longevity and performance still requires clear communication. The ability to show clients examples of metal shingle installations that are visually indistinguishable from traditional materials while offering substantially enhanced durability can be a powerful tool in justifying the investment to value-conscious clients.

The ROOFGLORY Advantage: Manufacturing Excellence and Technical Partnership

Precision Engineering and Production Capabilities

Our manufacturing approach at ROOFGLORY’s Linyi facility emphasizes precision engineering and consistent quality across both our panel and shingle product lines. The advanced production technology we’ve implemented ensures dimensional accuracy and performance consistency that simplifies installation and ensures long-term reliability. This manufacturing excellence provides tangible benefits for building professionals through reduced installation time, minimized material waste, and predictable performance outcomes.

The vertical integration of our manufacturing processes, from raw material selection through final packaging, ensures complete quality control throughout production. This integration allows us to maintain competitive pricing while delivering products that meet the exacting standards required by professional builders and their discerning clients. The result is roofing solutions that provide exceptional value throughout their service life, not just at the point of purchase.

Technical Support and Professional Collaboration

Our commitment to our professional partners extends beyond manufacturing to encompass comprehensive technical support throughout the project lifecycle. From initial specification through installation and beyond, our technical team provides expert guidance on system selection, detail development, and installation best practices. This collaborative approach ensures that ROOFGLORY products perform as intended across diverse applications and environmental conditions.

For importers and contractors seeking to expand their metal roofing offerings, we provide marketing support, installation training resources, and project-specific technical assistance that facilitates successful market entry and growth. This partnership philosophy distinguishes our approach from simple supplier relationships and reflects our commitment to the long-term success of our professional partners.

Conclusion: Strategic Material Selection for Professional Success

The decision between traditional metal roofing systems and metal shingle products ultimately reflects broader business strategy considerations beyond simple material cost comparisons. For building professionals focused on large-scale commercial projects or contemporary residential designs, traditional metal panels often provide optimal value through installation efficiency and clean aesthetic appeal. For those serving residential markets where traditional architectural character is valued, metal shingles offer a compelling combination of familiar aesthetics and superior performance.

At ROOFGLORY, we understand that successful material selection involves balancing immediate project requirements with long-term performance considerations. Our diverse product range ensures that building professionals can access the ideal roofing solution for each project’s specific needs, supported by manufacturing excellence and technical partnership that extends from our facilities in Linyi to job sites worldwide.

Ready to explore how ROOFGLORY metal roofing solutions can enhance your project outcomes and business positioning? Contact our technical team to discuss your specific requirements and discover how our roofing systems can deliver exceptional value for your operations.

Explore our comprehensive product range and technical resources:

Discover the ROOFGLORY difference—where strategic manufacturing partnerships deliver exceptional value in metal roofing solutions for building professionals worldwide.

Manufacturing Precision and Quality Control

Manufacturing Precision and Quality Control